LATHE MACHINE

Workpieces of short length, large diameter and irregular shapes, which can not be

mounted between centers, are held quickly and rigidly in chuck.There are different types of

chucks namely, Three jaw universal chuck, Four jaw independent chuck, Magnetic chuck,

Collet chuck and Combination chuck.

mounted between centers, are held quickly and rigidly in chuck.There are different types of

chucks namely, Three jaw universal chuck, Four jaw independent chuck, Magnetic chuck,

Collet chuck and Combination chuck.

a) Three Jaw Self-Centering Chuck

b) Four Jaw Independent Chuck

c) Magnetic Chuck

Three Jaw Self-Centering Chuck

equal amount by rotating any one of the three pinions by a chuck key.This type of chuck is

suitable for holding and rotating regular shaped workpieces like round or hexagonal rods

about the axis of the lathe. Workpieces of irregular shapes cannot be held by this chuck.

The work is held quickly and easily as the three jaws move at the same time.

|

| Three Jaw Self Centering Chuck |

Four Jaw Independent Chuck

There are four jaws in this chuck. Each jaw is moved independently by rotating a

screw with the help of a chuck key. A particular jaw may be moved according to the shape

of the work. Hence this type of chuck can hold woks of irregular shapes. But it requires

more time to set the work aligned with the lathe axis. Experienced turners can set the work

about the axis quickly. Concentric circles are inscribed on the face of the chuck to enable

quick centering of the workpiece.

|

| Four Jaw Independent Chuck |

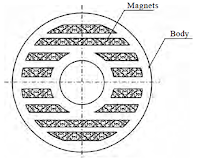

The holding power of this chuck

is obtained by the magnetic flux radiating from the electromagnet placed inside

the chuck. Magnets are adjusted inside the chuck to hold or release the work.

Work pieces made of magnetic material only are held in this chuck. Very small,

thin and light works which cannot be held in an ordinary chuck are held in this

chuck.

|

| Magnet Chuck |

Preet Lathe offers all of the above chuck fitted as well as standalone. Our range of All Geared Lathe Machine & Conventional Cone Pulley Lathe comes along with these chucks.